Many of the developing countries produce huge quantities of but they are used inefficiently causing extensive pollution to the environment. The major residues are rice husk, coffee husk, coir pith, jute sticks, bagasse, groundnut shells, mustard stalks and cotton stalks, … Continue reading

Our Model

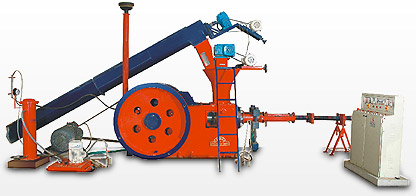

JUMBO 90 BIOMASS BRIQUETTING MACHINE

The flagship product of Radhe Industrial Corporation is Jumbo 90 Biomass Briquette Press. We offer our valued customers superior quality range of Jumbo 90 briquetting machine with following facts:

Jumbo 90 Biomass Briquette Press

We have introduced first time Jumbo 90 model in the year 1997 in India. Jumbo 90 briquetting press machine is RICO’s own discovery. Jumbo 90 biomass briquette press is a machine that converts agriculture waste into useful briquettes. This machine has high production capacity and consumes low electricity.

In this machine, raw materials are needed to feed into briquetting machine. Then raw materials are compressed under high pressure and give the output briquettes. This process does not contain sulfur that’s why this is known as binder less technology. In India, binder less technology is most successful and popular.

Technical Specification

| Model No | Jumbo 90 |

| Production capacity | 1500 Kg/Hr ± 20 % |

| Moisture Content | 10 to 12% Maximum (If higher than this, it would require to dry it.) |

| Raw Material Size | Up to 25mm Can be used directly |

| Finished Product size | 90 MM DIA |

| Finished Product Shape | Cylindrical |

| Power Requirement | 91HP |

| Biomass Type | Agro residues (cotton Salk, groundnut shells, almond shells, coffee husk and other agro residues |

| Process Cost Material | Rs. 400/- per MT. depending upon quality and density of raw material |

Features of Jumbo 90 Briquette Press

- High Production capacity

- Standard design with Heavy Structure

- Easy operating System

- Acceptability up to 25 mm size of raw material

- High density of finished product with 90 mm dia.

- Low production and maintenance cost

- Low electricity required due to direct feeding

- No air pollution due to does not contain any chemical

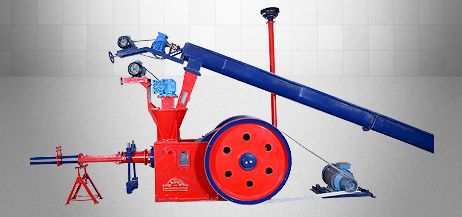

Super 70 Biomass Briquette Press

Super 70 biomass briquette press is specially designed by RICO for medium scale industries who want medium scale production of biomass briquettes. Super 70 is perfect suitable where availability of raw material is medium. This machine is technically innovative and made with superior quality so it doesn’t need stable supervision.

Super 70 is highly efficient and the credit of its high result also goes to our dedicated workers. It is useful in various industries like food & chemical industry, paper mills and fabric factories. RICO is supremely competitive in biomass briquetting machine manufacturing. Our perseverance, technology and dedication are only few reasons that make us a trustworthy organization across the globe.

Technical Specification

| Model No | Super 70 |

| Production capacity | 750 Kg/Hr ± 20 % |

| Moisture Content | 10 to 12% Maximum (If higher than this, it would require to dry it.) |

| Raw Material Size | 10 to 12 mm can be used directly |

| Finished Product size | 70 MM DIA. |

| Finished Product Shape | Cylindrical |

| Power Requirement | 49HP |

| Biomass Type | Agro residues (cotton Salk, groundnut shells, almond shells, coffee husk and other agro residues. |

| Process Cost Material | Indian Rs.660/- ± 10% |

Super 70 is the best briquetting machine with raw material up to 12 mm size. Some latest changes make it most effective and more economical model.

Hammer Mill for Biomass Briquette plant project

Hammer mill is a machine whose purpose is to crush aggregate raw material into powder form. It is used to make powder from agriculture and forestry waste.

The material with 0-100 mm is fed in the conveyor. It goes to Hammer Mill from the conveyor where it is ground with lots of blades which are there in the Hammer Mill. Then the final material is available which is fed into biomass briquetting machine to make briquettes. To convert aggregate raw material into powder form power requirement is 34 HP and input size of raw material is above 25 mm.

Technical Specification

| Model No | Hammer Mill |

| Production capacity | 1200/Kg (+- 20% Depending on Quality of Raw Material) |

| Raw Material Size | 01mm to 25mm |

| Finished Product size | Powder Form |

| Power Requirement | 34HP |

Features of Hammer Mill

- What is Briquetting Plant

- Briquetting Plant Models

- Why Buy Briquetting Plant From Us

- Benefits of Briquetting Plant

- Project of Briquetting Plant

- Features of Briquetting Plant

- Briquetting Machine

- Manufacturing of Briquettes

- Higlights of Briquetting Industry

- Video Presentations of Briquetting Machine (Plant)